Showroom

The purpose of slurry pump

coating is to protect metal surfaces against erosive and corrosive forces.

Slurry pumps may be safeguarded using these. Additionally, we provide solutions

for a wide variety of engineering issues and repair circumstances.

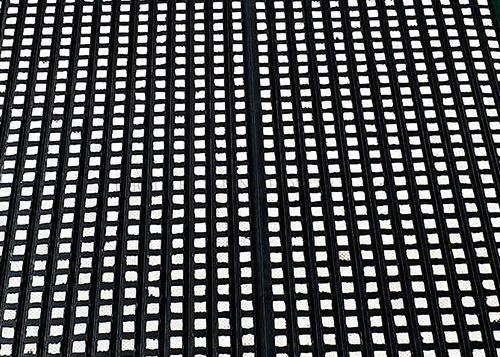

Our wear plate sheet's

flexibility is one of its key characteristics. While maintaining their original

shape, these can bend to absorb impact. Steel in these plates is resistant to

denting and buckling due to their high strength.

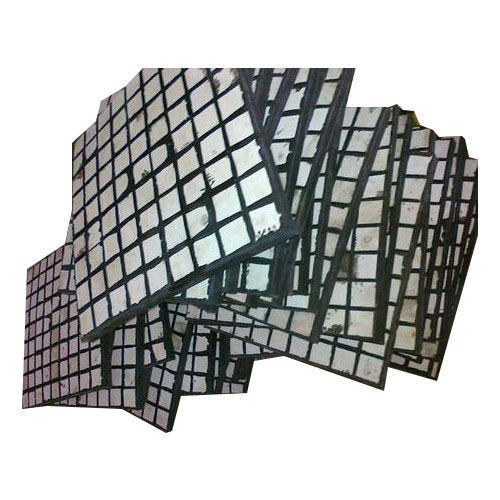

Rubber Embedded Ceramic offers outstanding wear resistance, while

rubber's elasticity effectively dampens impact pressures that may otherwise

break ceramics. The vibrations, noises, and impact shock caused by hitting

materials are also significantly diminished by the rubber.

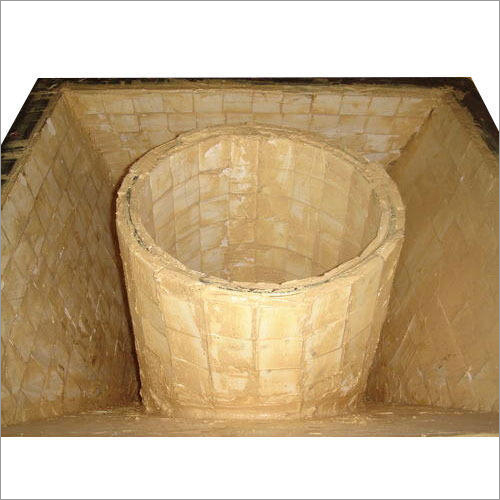

Due to their significant high temperature capacity, hardness, and

electrical qualities, technical ceramics

are widely utilized to replace metals, polymers, and refractory materials in a

range of applications. Their characteristics may be modified to fit a wide

range of challenging circumstances.

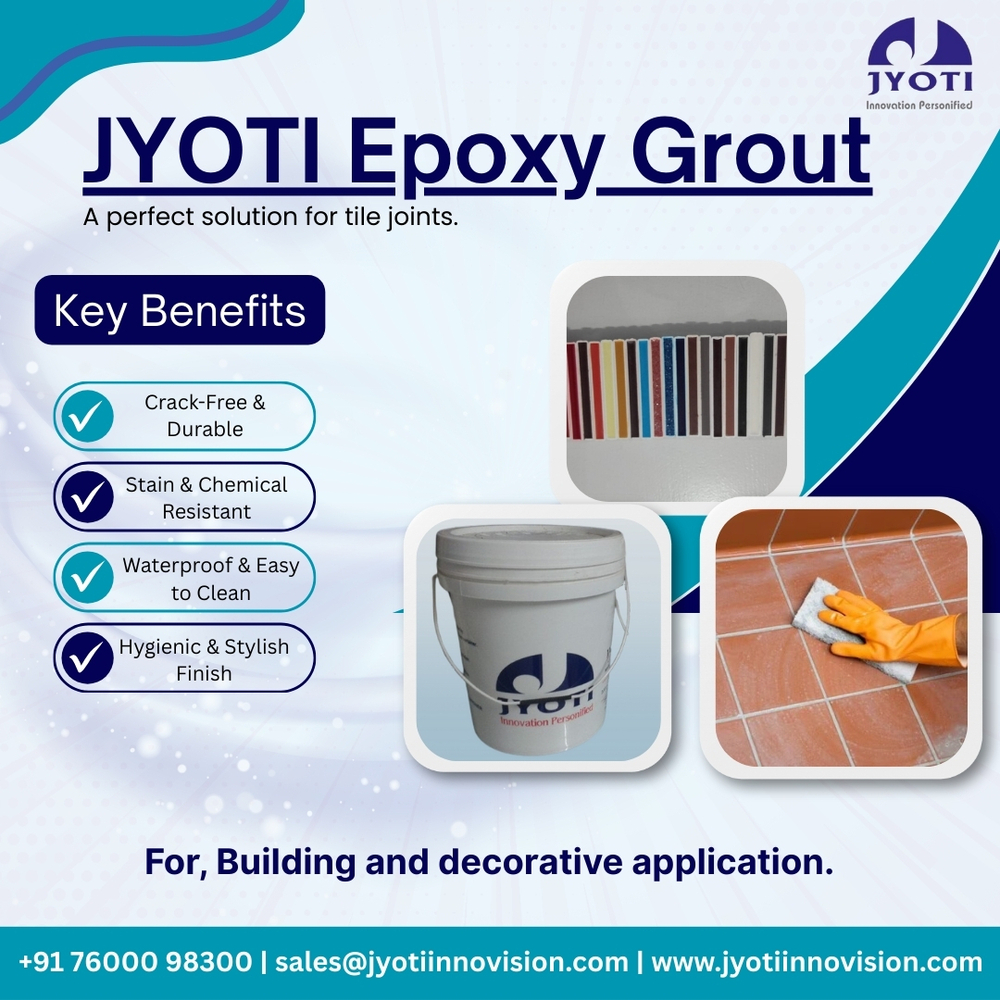

We provide you with a wide selection of tile adhesives that are resilient to weather changes, robust, and

long-lasting. For interior or exterior house projects, our adhesive formulas

may be used in a wide range of ways to fix various types of tiles and walls.